by lakeridge | Oct 14, 2019 | Commercial Paving, Residential Paving

You may have heard that salting asphalt roads, driveways and parking lots damages the pavement. There’s good news and bad news. Hot mix asphalt will not deteriorate when salted for de-icing purposes, but de-icers may exacerbate the effects of the freeze-thaw cycle and worsen existing potholes. Concrete driveways or parking lots are another story. Salt can damage the molecular bonds holding the concrete together, resulting in deterioration, weakened surfaces and compromised weight-bearing capacity. Asphalt driveway and parking lot owners shouldn’t celebrate prematurely though. Using rock salt to de-ice your driveway, parking lot or access roads can have negative consequences for local groundwater and living things, including animals and landscape features. What Are the Negatives of Salting Asphalt Pavement? Hot-mix asphalt is comprised of sand, petroleum and stone aggregate to maximize its stability and durability. One of asphalt’s beneficial attributes is a natural resistance to the potential damages of the freeze-thaw cycle. The asphalt formula also makes this type of pavement resistant to damage by salt. However, if asphalt paving is already in a degraded state, such as being riddled with potholes and cracks for example, the salt may potentially worsen damage caused by the freeze-thaw cycle. Salt will melt the water, which will stay liquid long enough to penetrate deeper and in larger quantities than it would if it were not salted. When the water does eventually freeze, it may further expand cracks and deepen/widen potholes. The salt itself isn’t the root cause but can be a contributing factor if the asphalt paving is poorly maintained or damaged prior to salting. Concrete, on the other hand, is vulnerable to...

by lakeridge | Oct 14, 2019 | Commercial Paving, Residential Paving

An asphalt overlay is a layer of new asphalt applied over the existing base layer of asphalt on a driveway, parking lot or road. These new layers are generally about 1.5- to 3-inches thick, depending on the demands on the asphalt and the depth of surface asphalt removed. An asphalt overlay should not be considered an adequate alternative to repaving in every case, but it is a way to significantly extend the useful life of your paved surfaces if the base of your pavement is still in good shape. When Is an Asphalt Overlay Appropriate? There are several signs that indicate it’s time for some type of reparative action, whether it’s an asphalt overlay, repaving or just patching. Some of these signs include: Cracks Uneven pavement surface Potholes Promptly having cracks and potholes filled and sealed will extend the life of your driveway or parking lot and prevent those issues from worsening due to weather, heavy use and the passage of time. Fixing defects and damages is also important from a liability standpoint. Potholes are tripping hazards and can damage vehicles. No business wants to see their customers or employees get hurt or damage their property during their visit. The restorative solution you choose should be based on the age of the asphalt pavement and the severity of the issues affecting your asphalt driveway, parking lot or road. If a commercial parking lot was repaved within the past five or 10 years, complete asphalt repaving is likely excessive. However, if potholes and cracks are causing frequent problems, basic patching may not be enough to address the underlying problems. A...

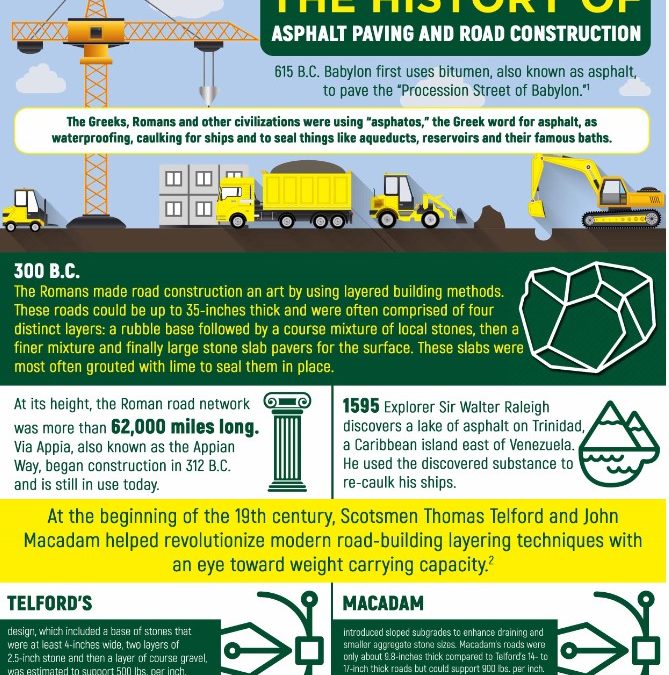

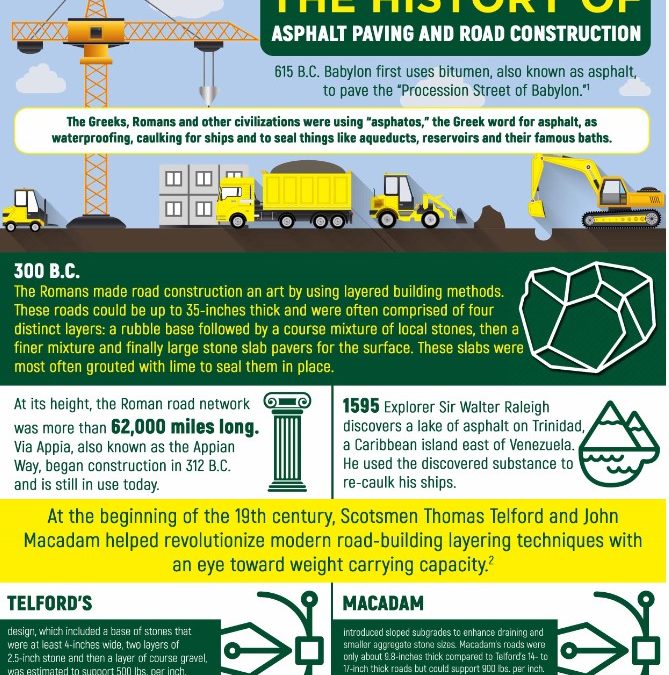

by lakeridge | Sep 20, 2019 | Commercial Paving, Residential Paving

See Full Infographic

by lakeridge | Aug 12, 2019 | Commercial Paving

Click here to see full infographic or to download

by lakeridge | Jul 10, 2019 | Residential Paving

Are you in the market for a new driveway and are trying to determine whether you should go with an asphalt driveway or a concrete driveway? The following are some important factors to consider when making your choice. Asphalt Driveways vs. Concrete Driveways Concrete driveways are, in general, one and a half to two times more expensive to install per square foot than asphalt driveways. This also means concrete driveways cost significantly more to repair compared with asphalt driveways. Some paving experts will tell customers that concrete driveways will last longer, but as with all home improvement services, the end results and their longevity has more to do with quality workmanship and materials than anything else. The other factor that will significantly impact the lifespan of any driveway, whether concrete or asphalt, is frequency of maintenance. A properly maintained asphalt driveway can last decades. Here are some other factors to keep in mind when trying to decide whether you want an asphalt driveway or a concrete driveway: It takes seven days of curing before you can drive on a concrete driveway, but you can drive on an asphalt driveway nearly right after it has been applied. When cracks do appear in an asphalt driveway they can be quickly and affordably repaired and resealed while still looking great. Cracks are harder to patch in concrete, are more noticeable and may require invasive, messy and time-consuming methods to fix. Asphalt is elastic enough to expand or contract with changes in temperature or when bearing heavy loads. Concrete driveways are more prone to crack in cold temperatures or under heavy weights. If...

by lakeridge | Jun 25, 2019 | Commercial Paving

How long after asphalt paving is completed can I drive on it? The length of time you should avoid driving on asphalt varies based on the job and weather conditions, but in most cases no more than 24 hours. If the weather is especially hot, which is thankfully rare in the Seattle area, we may recommend 48 hours for proper curing. Can asphalt be poured when it’s raining? It really depends on the asphalt paving contractors, their experience and the asphalt paving machines, materials and equipment they are using. We often have to deal with rainy or drizzly weather and can complete jobs even if the ground isn’t completely dry. The severity of rain and ground saturation may play a role in whether your job can be completed on schedule. We always strive to keep to our deadlines but never pave when the end result may not meet our high expectations. Can it get too cold to perform asphalt paving? In some parts of the world, temperature can impact when asphalt paving can be performed, but temperature is rarely an issue for Lakeridge Paving Company. One of the main variables that impacts whether asphalt paving can be performed at a given temperature is the thickness of asphalt being poured. The thinner a layer of asphalt is, the more quickly it needs to be compacted because it will lose heat at a faster rate than a thicker layer of asphalt. Deeper asphalt pours can be performed in cooler temperatures than shallow asphalt paving. Why should I consider asphalt paving instead of concrete paving for my driveway? Asphalt...

by lakeridge | Jun 25, 2019 | Commercial Paving

Those of us living in the Seattle, Tacoma and Olympia areas of the Pacific Northwest are very fortunate to be surrounded by some of the most beautiful landscapes the nation has to offer. There are countless breathtaking drives to be had around Olympic National Forest, Okanogan-Wenatchee National Forest, the Mt. Baker-Snoqualmie National Forest and Mt. Rainier National Park. The following are six drives that you may want to check out. Even the Islands Have Beautiful Drives Horseshoe Highway The shortest drive on this list, the Horseshoe Highway, is located on Orcas Island. Motorists who want to drive the Horseshow Highway will need to take the ferry that transports passengers and vehicles from Anacortes to Orcas Island, the largest of the San Juan Islands. The Horseshoe Highway takes motorists from Orcas Landing, where the fairy lets off, approximately 18 miles to the Mount Constitution parking lot. On a clear day, the Mount Constitution Lookout also gives visitors a breathtaking view of Mount Baker, Vancouver, Mount Rainier and the Olympic Mountain Range. Whidbey Island The drive through Whidbey Island also requires a ferry ride, this one approximately 20 minutes from Mukilteo. You’ll head from the Ferry to WA-526, then you’ll head west until it becomes WA-20. This drive, approximately 47 miles long, will take you through Langley, vineyards, South Whidbey State Park, 250-year-old trees in old-growth forests, the town of Coupeville and ends at Deception Pass State Park. Along the route are multiple opportunities for exploring places like Ebey’s Landing, Fort Casey State Park and the Meerkerk Rhododendron Gardens. Seattle Area Drives Cascade Valley Heritage Corridor This drive is unique because...

by lakeridge | Apr 1, 2019 | Commercial Paving

If your commercial parking lot is in need of repair, resurfacing or repaving, you may be wondering when the ideal time is to schedule the job. From a business perspective, it’s important to consider the impact a repaving project will have on your employees and customers. You ideally want to have the job performed at a time and on a schedule that will minimize disruption to your operations. There are other important factors to consider as well. In almost every case, warmer temperatures make for better asphalt paving conditions. Asphalt needs to be applied at high temperatures, and the asphalt mixture needs to maintain a high temperature while it’s being smoothed and compacted. Winter conditions can make doing this difficult, which can result in some asphalt companies leaving jobs with less than ideal results. For example, if the asphalt, delivered at 300-degrees Fahrenheit, is being applied 1.5 inches thick, and the surface temperature of the ground is only 40-degrees Fahrenheit, the asphalt contractors would only have about 16 minutes to compact the asphalt before it cools below approximately 175-degrees Fahrenheit, the point where it is no longer adequately malleable to finish the job properly. However, if the surface temperature were 80-degrees Fahrenheit those same asphalt contractors would have 24 minutes to compact the asphalt.1 The thicker the asphalt being applied, the longer asphalt contractors have to complete compaction, as the asphalt mixture will retain heat longer. Businesses in the Puget Sound area also have to contend with frequent moisture, which can also have a negative impact on asphalt paving results. All that being said, an experienced asphalt paving company...

by lakeridge | Mar 7, 2019 | Commercial Paving

Property owners have a lot of options when it comes to addressing a failing asphalt parking lot or access roads. There are many potential solutions that can extend the working life of your existing parking lot, and many things to consider if complete replacement really is the best option. Questions to Ask Yourself Before a Commercial Paving Job Consider your business’s parking lot and any specifics needs or problems you currently have that should be addressed: Are there areas that tend to accumulate more standing water than others? Consider inspecting your paved areas after a rainstorm to identify areas that may have problematic draining. Does your current parking situation meet your needs? Lines can be adjusted to accommodate more vehicles or give vehicles more space in each spot. Do you have any problems with people speeding or driving recklessly in your parking lot? Having your property’s parking lot or driveways repaved is a good opportunity to add speedbumps or other traffic calming features. Do you have any major building construction projects coming up? It’s advisable to have construction or renovation projects completed first so construction vehicles don’t damage your newly paved commercial parking lot. When is the best time to have the job performed? Even if you decide to overhaul your existing parking lot, you’ll want to choose a time when the project will have minimal impact on your business’s operations. Is Repair an Option? There are some circumstances when it may make sense to have potholes professionally patched or cracks properly filled rather than pay for a larger-scale job. At Lakeridge Paving, we always encourage businesses with asphalt...

by lakeridge | Feb 5, 2019 | Commercial Paving

Most people probably don’t give airport paving much thought when they’re sitting in the terminal waiting for a flight. It’s one of the less thrilling aspects of an aviation industry that literally sends people soaring through the sky. But maybe we should be appreciating it more than we do, especially when taking into account just how integral they are to ensuring safe arrivals and departures. It’s pretty astonishing they seem to hold up as well as they do. Airports are one of the few places that don’t take any days off. Whether it’s Christmas Day, the middle of the night or raining cats and dogs, planes are still taking off and landing on the “tarmac.” Don’t Call Them Tarmacs in Front of an Enthusiast The folks at Aerosavvy really want you to know that “It’s NOT A Tarmac!” Tarmac is actually most commonly used as another term of asphalt. If you visit the United Kingdom you may notice people referring to what we commonly call asphalt as “tarmac.” If you really wanted to get technical about it, tarmac is its own separate paving method. Its full name is tarmacadam, which was named after John Loudon McAdam. He created a process known as “macadamizing,” wherein crushed gravel is applied to the surface of a paved road. The tarmac most people know today was actually patented by Edgar Purnell Hooley in 1901, although he didn’t really come up with the paving solution himself. Rather, he was driving past a tar factory and noticed that tar had been accidently spilled onto a “macadamized” road. Someone had covered that tar spill with more...